5nm in the USA: TSMC's Board Approves $3.5 Billion Fab in Arizona

TSMC's Arizona fab on track to start construction in 2021

Taiwan Semiconductor Manufacturing Co.'s board of directors has approved spending $3.5 billion on the company's upcoming fab in Arizona. The project will be co-financed by TSMC, the state of Arizona, and the U.S. federal government. The first commercial wafers are expected to be produced at the fab in 2024.

A $12 Billion Plan

"Approved an investment to establish a wholly-owned subsidiary in Arizona, United States of America, with a paid-in capital of US$3.5 billion (approximately NT$99.75 billion)," the statement by TSMC reads.

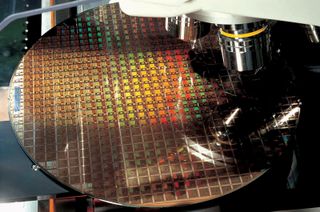

Construction of the fab is scheduled to start in 2021 and the fab is projected to start high-volume production in 2024. The initial production capacity target of the facility is about 20,000 wafer starts per month (WSPM) and one of the nodes to be used there is TSMC's 5 nm, which probably means N5 as well as N5P fabrication technologies. TSMC’s evolutionary N4 process might land there as well, but the company has not formally announced this.

In total, TSMC plans to spend $12 billion on its fab in Arizona from 2021 to 2029. The factory will employ about 1,600 people directly and thousands more indirectly. Keeping in mind that Intel Corp. already has multiple fabs in Arizona and Oregon, TSMC will not have to build a semiconductor industry supply chain from scratch, but rely on local suppliers.

TSMC’s Most Advanced Non-Taiwan Fab

In recent years, all of TSMC's advanced chips were produced solely in Taiwan. The company also owns a 200-mm Fab 10 in Shanghai, 300-mm Fab 16 in Nanjing, 200-mm WaferTech in Camas, Washington, and co-owns 200-mm SSMC in Singapore. These facilities are not quite in the same league as the company's domestic fabs that produce chips using leading-edge process technologies, such as 7 nm and 5 nm nodes.

TSMC's fab in Arizona will be the foundry's most advanced production facility outside of Taiwan, but it is not going to use the company's most sophisticated N3 node in 2024. TSMC's 3 nm technology is expected to enter volume production in the second half of 2022 in Taiwan and so far, the company has announced no plans to bring it to its U.S. subsidiary.

TSMC's key customers — Apple, Altera/Intel, AMD/Xilinx, Nvidia, Qualcomm and many others — are from the U.S. Clients like Apple and Qualcomm tend to use the company's most advanced fabrication technologies, but also place the largest orders as they have very significant volume requirements. This is why TSMC tends to build so-called GigaFabs in Taiwan, facilities with a production capacity north of 100,000 WSPM. So, while bringing N5/N5P/N4 to the U.S. in 2024 seems like a good idea overall, the 20,000 WSPM fab may not serve TSMC's high-volume customers from North America until several years down the road.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Improving Competitive Positions in the USA

But the fab in Arizona clearly improves ties between TSMC and the U.S. government, which is good for TSMC’s military chip business and might be good if the federal government decides that it needs to produce chips for other sensitive applications solely in the USA.

Owning an advanced fab in the USA also makes TSMC more competitive with GlobalFoundries, which has been working hard for years to land orders for military and non-military U.S.-developed chips that need to be produced in America, as well as Samsung Foundry, which does not produce any sub-10 nm chips in the U.S.

Last but not least, by running a fab in Arizona, TSMC will inevitably have to attract more American talent, which again makes it more competitive in general since these people will not work for other makers of semiconductors.

Taiwan Set to Remain TSMC’s Manufacturing Stronghold

With a plan to spend $12 billion on its Arizona fab in the U.S., TSMC clearly expands its presence in the country and while initial production volumes are not going to be high (20,000 WSPM is not a large fab by TSMC’s standards), the company scores a number of other goals with its new production facility. Eventually production capacities in the U.S. may be expanded, but for the foreseeable future Taiwan will remain the company’s manufacturing base.

The same board meeting that approved the $3.5 billion investment in the Arizona fab also approved capital appropriations of approximately $15.1 billion (approximately NT$430.6 billion) to build new manufacturing capabilities in Taiwan.

The giant investments will be used to build a new fab (presumably we are talking about TSMC’s fab near Hsinchu, Taiwan, that will be used to make 2-nm chips towards the middle of the decade), expand leading-edge production capacities, install new tools to offer specialty process technologies, install or upgrade advanced packaging fabs, and on research and development in Q1 2021.

Typically, TSMC tends to spend tens of billions of U.S. dollars every year on CapEx in Taiwan and such investments can hardly be compared to $3.5 billion the company intends to spend in Arizona.

Anton Shilov is a Freelance News Writer at Tom’s Hardware US. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

mihen Arizona and Nevada make alot of sense for manufacturing. The climate makes the region capable of manufacturing 24/7 365. The issue is really with the supply chain. Lack of infrastructure and access to resources.Reply -

nofanneeded Replymihen said:Arizona and Nevada make alot of sense for manufacturing. The climate makes the region capable of manufacturing 24/7 365. The issue is really with the supply chain. Lack of infrastructure and access to resources.

How is that true ? Nevada is very hot and needs air conditioning half of the year. reaches 120F... -

GenericUser Replymihen said:The issue is really with the supply chain. Lack of infrastructure and access to resources.

Well, the article implies that supply infrastructure isn't going to be an issue:

In total, TSMC plans to spend $12 billion on its fab in Arizona from 2021 to 2029. The factory will employ about 1,600 people directly and thousands more indirectly. Keeping in mind that Intel Corp. already has multiple fabs in Arizona and Oregon, TSMC will not have to build a semiconductor industry supply chain from scratch, but rely on local suppliers.

-

jkflipflop98 The climate is irrelevant when you're talking about a fab facility. The air inside is conditioned, humidfied, and filtered 10 times a minute.Reply

The real boon here is that they can piggyback off Intel's supply chain in the area to get up and functional fast. -

gg83 And don't forget about the potential for solar power. It gets very cold at night in the desert so that will save power half of the day maybe.Reply -

nofanneeded I think high tech fabs should be located in better areas with better climate and more green zones , not the desert .Reply

People who will work there are highly educated graduates and I hate working there all my life.

They deserve better life. -

jimmysmitty Replymihen said:Arizona and Nevada make alot of sense for manufacturing. The climate makes the region capable of manufacturing 24/7 365. The issue is really with the supply chain. Lack of infrastructure and access to resources.

I would bet they will also probably go to Chandler like Intel is currently in since it will have more of the supply chain developed.

gg83 said:And don't forget about the potential for solar power. It gets very cold at night in the desert so that will save power half of the day maybe.

Yea not quite. There are days here in Arzona during the summer where it never drops below 90F even at night. But other than a couple of months of extreme heat its nive the rest of the year.

nofanneeded said:I think high tech fabs should be located in better areas with better climate and more green zones , not the desert .

People who will work there are highly educated graduates and I hate working there all my life.

They deserve better life.

Most green zones have multiple seasons and other weather issues that make it harder to manufacture year round. Here in Arizona we have monsoon season which can be bad but its only for a few days out of a few months of the year.

You can golf during winter here, there are plenty of lakes and green areas close enough by to be able to make a weekend trip to (Flagstaff is very green and Lake Pleasant is pretty big). Its not as bad as people make it out to be. Sure when its hot its very hot but its a decent place to live. We don't have earthquakes and are not super expensive (California), Hurricanes (east coast/gulf coast), rarely a tornado (Midwest) and we don't freeze over often (super rare but we do get snow or very cold once in a while).

For a business its damn near perfect especially if they are manufacturing products. -

nofanneeded Replyjimmysmitty said:Most green zones have multiple seasons and other weather issues that make it harder to manufacture year round. Here in Arizona we have monsoon season which can be bad but its only for a few days out of a few months of the year.

You can golf during winter here, there are plenty of lakes and green areas close enough by to be able to make a weekend trip to (Flagstaff is very green and Lake Pleasant is pretty big). Its not as bad as people make it out to be. Sure when its hot its very hot but its a decent place to live. We don't have earthquakes and are not super expensive (California), Hurricanes (east coast/gulf coast), rarely a tornado (Midwest) and we don't freeze over often (super rare but we do get snow or very cold once in a while).

For a business its damn near perfect especially if they are manufacturing products.

I know but still ...

Intel Fab 24 Ireland

Intel Fab 42 Arizona

-

mihen Looked into it a bit further. Arizona makes perfect sense for a Fab if its for AMD CPUs, Apple, and Foxconn. Close to resource production and board partners in the US.Reply -

intelProcessEng Replynofanneeded said:How is that true ? Nevada is very hot and needs air conditioning half of the year. reaches 120F...

The benefits or Arizona are stable geology, dry air, and stable weather. The most critical of these three is stable geology because even the smallest of vibrations can impact lithography operations.

All Fabs are climate controlled of course, but the better the surrounding environment is, the lower the facilities burden to control a Fab's climate becomes. If the air outside is an order of magnitude lower, your filters only need to be 1/10th as effective.

However all of this is trumped by the real benefit of Arizona. Cheap land, relatively cheap cost of living which results in cheaper workers, yet a high talent pool because of the population and other technology businesses.

Most Popular