3-D X-ray tomography scoops up information about ice cream microstructure

There's nothing quite like an ice cream on a hot day, and eating it before it melts too much is part of the fun. Ice cream is a soft solid, and its appeal is a complex combination of 'mouthfeel', taste and appearance, which are all strongly affected by the underlying microstructure. We know that changes in the microstructure of ice cream occur at storage temperatures above -30°C, so they will occur during shipping, and in freezers at the supermarket and at home. In their ongoing quest to create the perfect ice cream, an international team of researchers brought samples to Diamond to investigate the temperature dependence of these microstructural changes, and the underlying physical mechanisms that control microstructural stability.

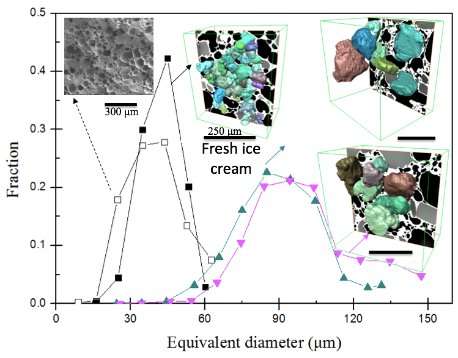

Previous research has examined coarsening of the microstructure with light microscopy and cryo-scanning electron microscopy, and transmission electron microscopy, but these techniques only provide 2-D information of the surface or of cuts through the ice cream sample. 3-D X-ray tomography provides far more information, and for their first set of experiments at Diamond, the team used ice cream samples that had been thermally 'abused' beforehand, by cycling them between -15°C and -5°C for a number of days. The results showed that both ice crystals and air cells within the ice cream foam grew in size for up to 14 cycles, with a growth rate that decreased significantly after 7 cycles.

These ex situ studies couldn't show the interactions between the microstructural features, and so for their most recent set of experiments, the team brought ice cream samples that had been thermally cycled through 7 cycles to Diamond, and then examined them during a further 7 cycles on the Diamond Manchester Beamline (I13-2). They developed a new data reconstruction and image processing method to segment and quantify the large dataset resulting from these time-resolved studies.

The results revealed that that melting and recrystallisation is responsible for changes to ice crystal size and shape during thermal abuse, whereas the changes in air bubble size and interconnectivity are mainly due to the bubbles coalescing.

According to Professor Peter Lee of the Research Complex at Harwell:

"This work also revealed other interesting phenomena, including the role of the unfrozen matrix in maintaining the ice cream's microstructural stability and the complex interactions between ice crystals and air bubbles. For example, the melting and recrystallisation of ice crystals significantly affect the air bubbles' morphology and the behaviour of the unfrozen matrix."

The team's results provide crucial information enhancing the understanding of microstructural evolution in ice cream and other soft foods. The experimental set-up and image processing routines developed are applicable to a wide range of soft materials.

More information: Enyu Guo et al. Revealing the microstructural stability of a three-phase soft solid (ice cream) by 4D synchrotron X-ray tomography, Journal of Food Engineering (2018). DOI: 10.1016/j.jfoodeng.2018.05.027

Provided by Diamond Light Source